Izinzuzo:

Ukusebenza okulula: Isakhiwo somugqa owodwa wokupholisa we-Strage Strand Cooding Granution lilula, ngezinga eliphakeme lokuzenzakalela, futhi kulula ukusebenza nokugcina.

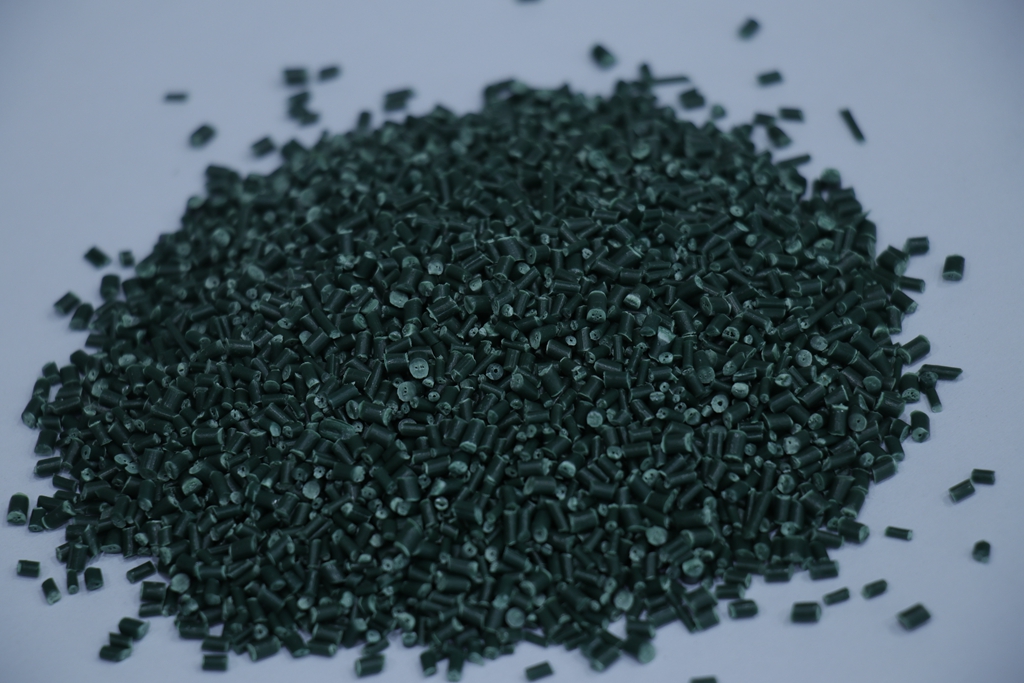

Ukusebenza kahle kokukhiqizwa okuphezulu: Ngokwakheka okwenziwe kahle, ukukhiqizwa kwe-granule yepulasitiki efanelekile kungatholwa ukufeza izidingo zokukhiqizwa kwabantu abaningi.

Ukuqina okuqinile: Imishini ilungele ukugadla kwezinto ezahlukahlukene zepulasitiki, njenge-PP, PE, PA, I-PS, TPU, njll., Futhi kungahlangabezana nezidingo zeplastiki zeplastiki zemikhakha ehlukahlukene.

Ikhwalithi yomkhiqizo eqinile eqediwe: Ingafinyelela ukuncibilika okungcono kanye nemiphumela yokuxuba, ukuqinisekisa ukuwohloka okufanayo kanye nekhwalithi yomkhiqizo ephezulu.

Okokusebenza okuyinhloko:

I-Screw feeder: I-Screw Feeder inesibopho sokudlulisela ipulasitiki ngokuzenzakalela ku-feeder. Kuqinisekisa ukuthi izinto ezibonakalayo zingena emgqeni wokukhiqiza ngokulinganayo futhi ngokuqhubekayo ngokudlulisela kwesikulufa, kunciphisa ukuphathwa ngesandla, futhi kuthuthukisa ukusebenza kahle kokukhiqiza.

I-feeder: I-feeder ilawula ukuhlinzekwa kwepulasitiki okulinganiselwe ukuze kuqinisekiswe ukuthi okuqukethwe okufaka i-extruder kuyazinza futhi umfaniswano. Lokhu kuqinisekisa ukuncibilika okufanayo nokwakheka kweplastiki yepulasitiki ngesikhathi senqubo elandelayo ye-granution. Ingaguqula isivinini sokuphakelayo ngokuya ngezidingo zokukhiqiza futhi ithuthukise ukuguquguquka komugqa wokukhiqiza.

I-Extuder: I-extruder imishini eyisisekelo yomugqa we-granution, obhekele ukufudumeza, ukuncibilika nokukhipha izinto zokwakha zepulasitiki.

Isiguquli sesikrini: Isetshenziselwa ukuhlunga ukungcola kupulasitiki ebilisiwe ukuze kuqinisekiswe ikhwalithi yama-pellets epulasitiki akhiqizwayo. Imishini ingangena esikhundleni sokuhlunga ngaphandle kokumisa umshini, ngcono ukuqhubeka nokusebenza kahle komugqa wokukhiqiza.

I-Dehydrator: Umsebenzi we-dehydrator ukuphola futhi ucwilisa imichilo yepulasitiki esanda kukhishwa. Lungiselela inqubo elandelayo ye-pelletetizing.

Isikrini sokudlidliza: Isikrini sokudlidliza sisetshenziselwa ukuhlukanisa izinhlayiya zepulasitiki zamasayizi ahlukene ukuqinisekisa ukuthi usayizi wezinhlayiyana umfaniswano futhi uhlangabezana nezidingo zokucaciswa komkhiqizo.

Silo: Isilo sisetshenziselwa ukugcina izinhlayiya zepulasitiki, ezisiza ukufakwa okulandelayo noma ezokuhamba.

Isikhathi Sokuthumela: Oct-18-2024