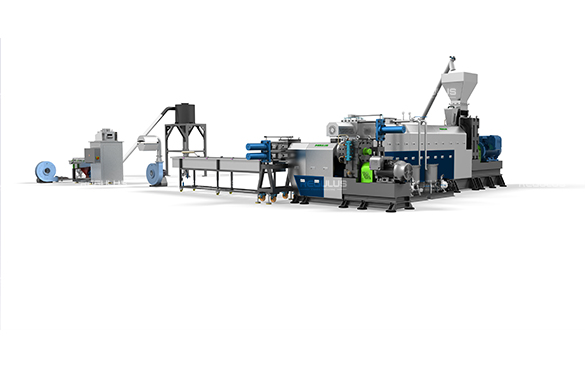

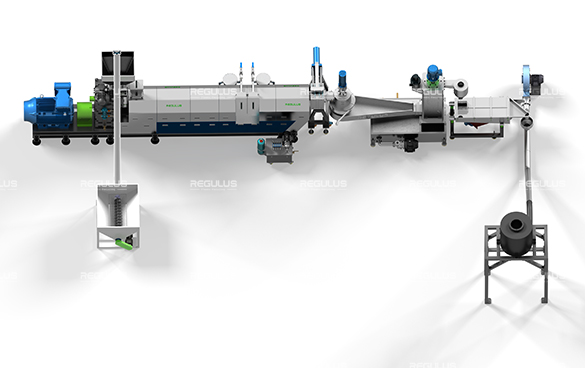

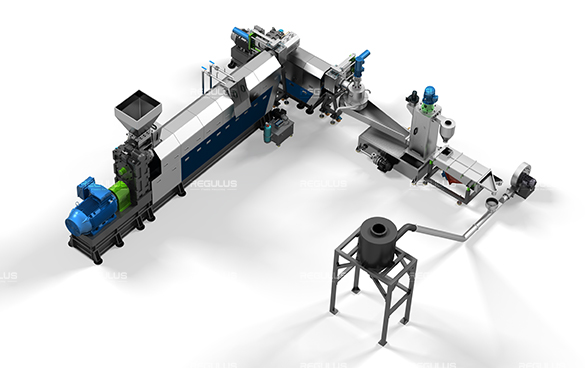

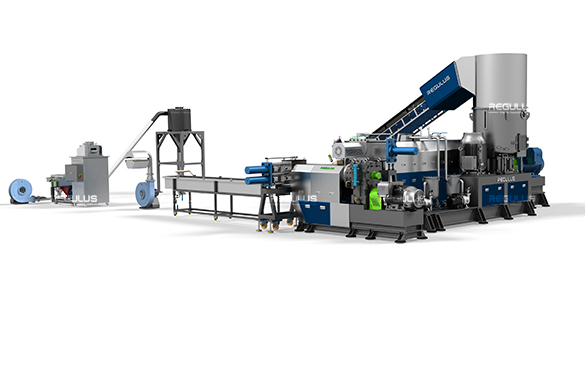

I-PP PP PET FLMINCECATION SING SINGE PRECYCLING ne-Granution Production Line

Ukucacisa

| I-Target Recycled Material | HDPE, LDPE, PP, BOPP, CPP, OPP, PC, PS, PS, Pu, AB | |||||

| Ukwakheka kwesistimu | I-Belt Ponveyor, ukusika i-Compact, i-Screw Screw Extredrer, i-Filtration,I-Pelletizer, Idivaysi yokupholisa amanzi, isigaba se-dehydration, fan converor, umkhiqizo silo. | |||||

| Impahla yesikulufa | I-38crmoala (sacm-645), i-bimetal (ngokuzithandela) | |||||

| L / d wesikulufa | 28/1, 30/1, 33/1, (Ngokwezici zokuphinda usebenzise kabusha) | |||||

| I-heater ye-barrel | I-Ceramic heater noma i-heater evuthayo | |||||

| Ukupholisa umphongolo | Ukupholisa komoya kwabalandeli ngokusebenzisa ama-blowers | |||||

| Uhlobo lwe-pelleting | Ama-pelletizing-ring we-pelletizing / amanzi-strands we-pelletizing / ngaphansi kwamanzi | |||||

| Izinsizakalo Zobuchwepheshe | Idizayini yephrojekthi, ukwakhiwa kwefekthri, ukufakwa nezincomo, ukukhomiswa | |||||

| Imodeli yomshini | Inkambeka | L / d | Isikulufa esisodwa | |||

| Ukuvimbanisa | Amandla emoto | Isikulufa ububanzi | Extruder motor | Umthamo wokuphuma | ||

| (Litre) | (kw) | (MM) | (kw) | (kg / h) | ||

| Xy-85 | 350 | 37 | 85 | 33 | 55 | 150-250 |

| Xy-100 | 500 | 55 | 100 | 33 | 90 | 250-350 |

| Xy-130 | I-850 | 90 | 1350 | 33 | 132 | 450-550 |

| Xy-160 | 1100 | 110-132 | I-160 | 33 | 185 | I-650-800 |

| Xy-180 | I-1500 | 185 | Umfana no-180 | 33 | 250-280 | 900-1100 |

Isistimu yePellecling Pelletizing yePullelcling Plastic Recycuting Pelleting Pelleting

Uchungechunge oluhlanganisiwe nohlelo lwe-pelletizing luhlanganisa umsebenzi wokuchotshozwa, ukuhlamba, ukusatshalaliswa kwepulasitiki kanye ne-pelletizing kusinyathelo esisodwa. Kusetshenziswe kwinqubo ye-plastics recyclng ne-pelleting. Uhlelo lwe-ACHS TM luyikhambi elithembekile nelisebenza kahle kwefilimu ye-plastics, ama-raffis, ama-filaments, izikhwama, izikhwama ezilukiwe kanye nokutshalwa kwezinto zokwakha umshini wokuphindaphinda. Kunganikeza okuphezulu okuphezulu kepha nge-Lowed Energy Consure Phunt. Isicelo: PE, pp, Ps, Abs, XPS, EPS, PVB.

Ukondla

Njengomklamo ojwayelekile, imidwebo yepulasitiki efana nefilimu, i-filament, uRafis udluliswa egumbini elihlangene ngebhande lokuhambisa; Ukuphatha ama-Rolls 'ama-Scraps, ukuRobela Ukudonsa idivaysi kuyindlela yokudla ongakukhetha. Izimoto zokushayela zebhande le-convevor kanye nokudonsa idivaysi kubambisana ne-inverter. Ijubane lokondliwa kwebhande lokuhambisa noma i-roll hauling athoma ngokuzenzakalela ngokususelwa ekusekelweni kwegumbi le-compactor.

Ukuchoboza nokuhlangana

I-Compact ifakwe idivaysi eqeda umoya. Ngomsebenzi owenziwa ngomshini wommese we-rotor kanye nommese we-stator ezansi kwe-compact, izinga lokushisa le-compact kanye nezinto ezibonakalayo zizokhula kancane ngemuva kokuqina nokushayisana kanye nomswakama wezinto ezingavuthiwe kuzontanta phezulu kwe-compactor. Idivayisi ingasusa ngempumelelo umswakama nothuli, oluzogwema ukusetshenziswa okwengeziwe kwamandla ukubhekana nomswakama.Lis Compact kuhlanganisa ukufudumala kwangaphambili, ukuncishiswa kwangaphambi kokomile nokuqina ukuze uqinisekise okusheshayo futhi okuzinzileinqubo yokudla.

Ama-Atatory ama-blades we-compact

I-blade ejikelezayo kanye ne-fided fidet cut okuqukethwe kube ngama-flakes amancane. Ukufudumala okungqubuzanayo okukhiqizwe ama-blade ajikelezayo aphezulu azoshisa azoshisa futhi anciphise ama-flakes.

Isikulufa esisodwa

Umklamo wethu oyingqayizivele u-Screw Screw Extreder ngobumnene upristives futhi uhlele izinto zokwakha. I-extruder yethu ye-bi-metal inokumelana okukhulu kokulwa nokugqwala, gqoka isikhathi sokungamelana nokungamelana nempilo.

Izindawo eziphindwe kabili ze-vacuum degassing

Ngezindawo eziphindwe kabili ze-vacuum degassing, ama-shuqu

Ipuleti hlobo Screen Changer

Isihlungi sohlobo lwepuleti senziwa ngohlobo oluqhubekayo ngamapuleti amabili okuhlunga. Okungenani isihlungi esisodwa esisebenza lapho isikrini siguqula.I-heater ekhethwe njenge-heater yokushisa okungaguquki nokuzinzile

Akukho-isihlungi sohlobo lwe-piston stop

1.a Isiguquli sesikrini esisezingeni eliphansi / i-piston kabili-scrapng screen noma ipuleti elingenzi-maton / i-piston yesiteshi esine lingafakwa ekhanda le-extruder ukwethula ukusebenza okubalulekile kwe-filltration.

I-2.long Screen Lifetime, imvamisa ephansi yokushintsha kwesikrini: impilo yokuhlunga ende ngenxa yezindawo ezinkulu zokuhlunga.

3. Kulula ukuyisebenzisa futhi akukho hlobo lokuma: Ukushintshwa kwesikrini okulula futhi okusheshayo futhi akudingeki ukuyeka umshini osebenzayo.

Izindleko eziphansi zokusebenza eziphansi.

Uhlelo lwe-vertical waw ring ring granution

1.Ngoma-sishintsha i-pelletiziin ikhanda le-puolity enhle kakhulu ye-gransate kanye nesikhathi eside sibonga ngokungafanele ama-blades arsure afanele.

2. I-RPM yama-Blades ajikelezayo anokuzenzakalelayo ngokususelwa ekunciphiseni ingcindezi extress.

I-3.Easy and Fast Pelletizer blades changever, ngaphandle komsebenzi wokulungiswa konga isikhathi.

Uhlelo lwe-Horizontal Water Ring Granution System

1.Ngoma-sishintsha i-pelletiziin ikhanda le-puolity enhle kakhulu ye-gransate kanye nesikhathi eside sibonga ngokungafanele ama-blades arsure afanele.

2. I-RPM yama-Blades ajikelezayo anokuzenzakalelayo ngokususelwa ekunciphiseni ingcindezi extress.

I-3.Easy and Fast Pelletizer blades changever, ngaphandle komsebenzi wokulungiswa konga isikhathi.

Ukudlidliza owomile

Isihlungi se-Vibration esingenzeleli esingu-1.adwa sihlanganisa nge-centrifugal yohlobo lwe-centrifugal etholwayo yokusebenza okuphezulu okuphezulu kwe-pellets eyomile kanye nokusetshenziswa kwamandla okuphansi.

2. Hlanganisa amaviki: Amavie afakiwe futhi ahlelwe ngezikulufo esikhundleni sokufudumala, ukuze ukwazi ukushintsha ama-naever kalula ngokuzayo.

I-vertical Particle deHydrator

Isetshenziselwa ngokukhethekile ukomisa kwamasongo amanzi epulasitiki kanye nezinhlayiya ezingaphansi kwamanzi,

ukudlidliza isikrini

Isetshenziselwe ukuhlukanisa usayizi wezinhlayiya zepulasitiki